Print Driver Tour

General Tab

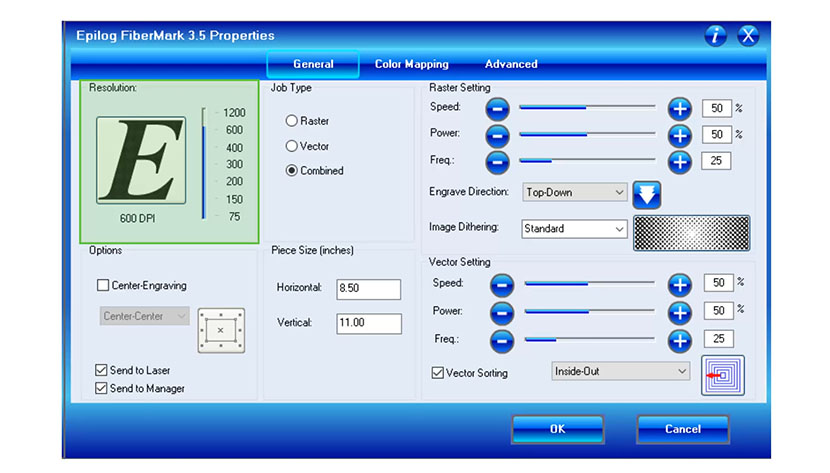

We’ll start on the General tab.

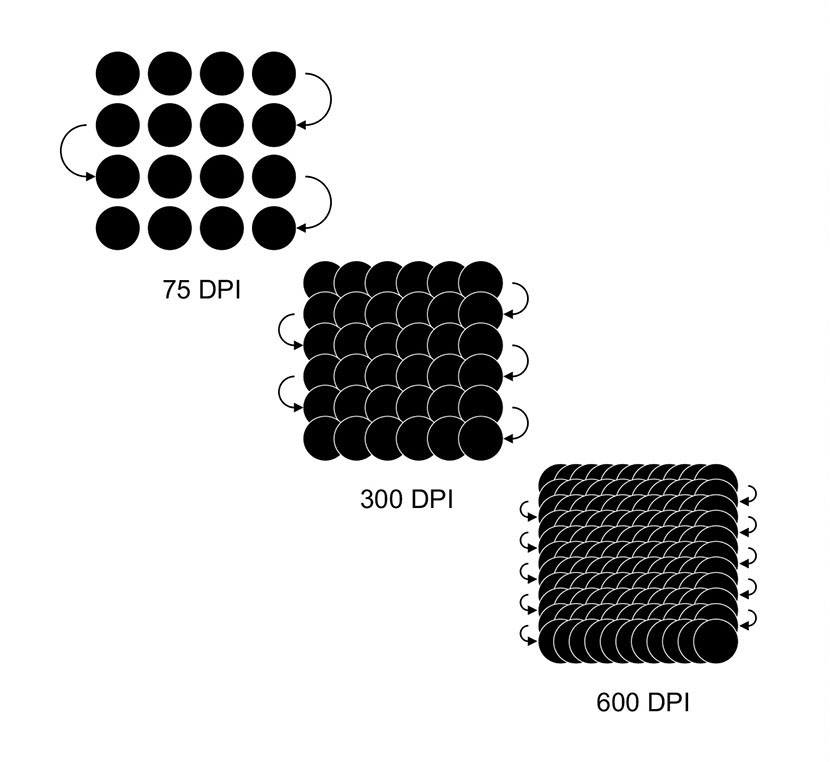

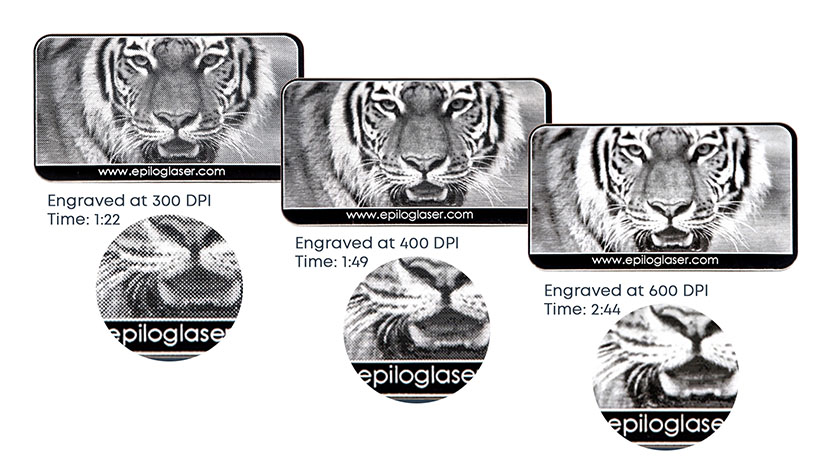

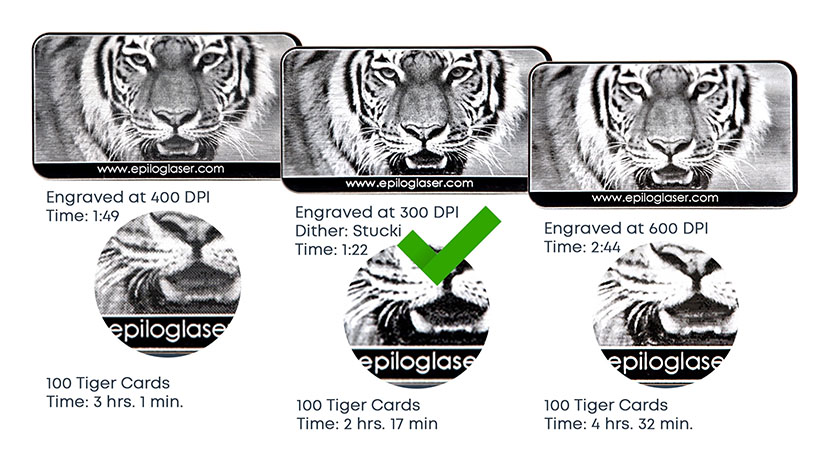

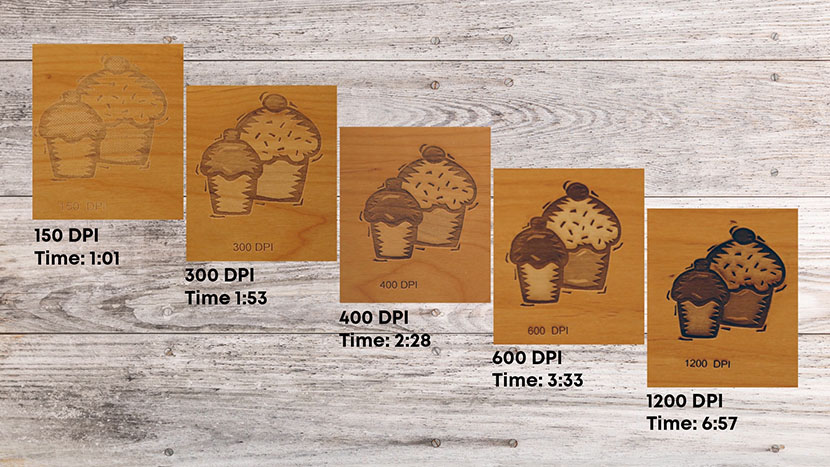

First, at the top left corner of the driver you’ll find the “Resolution” settings, which can be set from 75 to 1200 DPI. The higher you set the resolution, the higher your engraving quality will be. Typically you will use 400 or 600 DPI for most materials you engrave.

The “Job Type” area is where you choose between Raster, Vector, or Combined modes, which includes both engraving and cutting within the same job.

The “Raster Setting” area is where you will set your speed and power settings, from 1 to 100%. You can find suggested speeds and powers for different materials in your manual.

The “Engrave Direction” setting can be set to Top-Down or Bottom-Up by clicking the arrow button or using the drop-down menu.

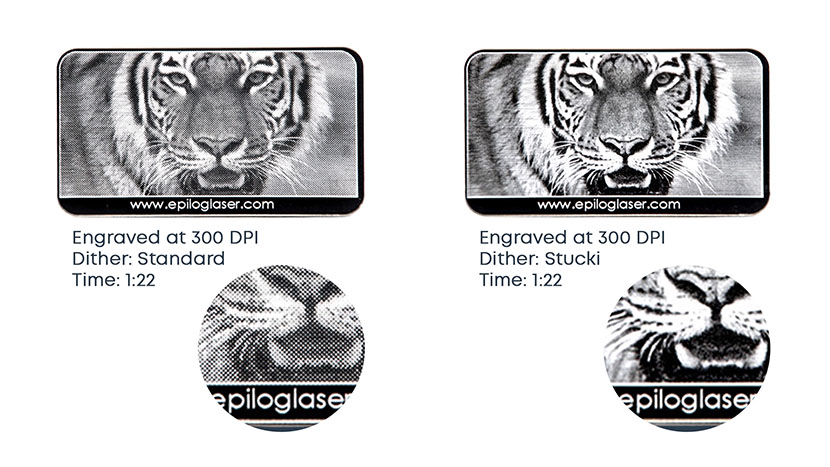

The “Image Dithering” setting is a drop-down menu where you can choose between different ways for the laser to interpret the dot pattern in your file. There are three clipart modes: Standard, Brighten, and Low Res when running lower resolution images. The next three modes, Floyd Steinberg, Jarvis, and Stucki are all used for different types of photographs.

Next, you can set your Vector settings. Start with your speed and power settings, setting each from 1 to 100%.

The Vector frequency setting ranges from 1 to 100. This is the pulsing rate as well as the average output power per pulse of the laser. When engraving or etching metal materials, lower frequency settings will produce a darker mark, while a high frequency will produce the best quality mark on plastics.

The “Vector Sorting” checkbox will determine the order of your cut lines. With Vector Sorting off, the laser will cut in the order that your objects or lines were created.

In the drop-down box, you can select the sorting mode. It is set to “Optimize” as a default. Selecting “Inside-Out” sorting will first cut out the most interior items, then outer ones. For example, the letter O will first cut the interior circle, followed by the outer one.

Selecting “Optimize” sorting chooses the next closest starting node.

The “Piece Size” setting is where you will set your page size dimensions to match the page size of your design.

The Center-Engraving checkbox will enable the center-engraving features of the laser. Choose your new home position and the laser will center your engraving around that position. You can choose between left-center, top-center, page-center, and center-center positioning.

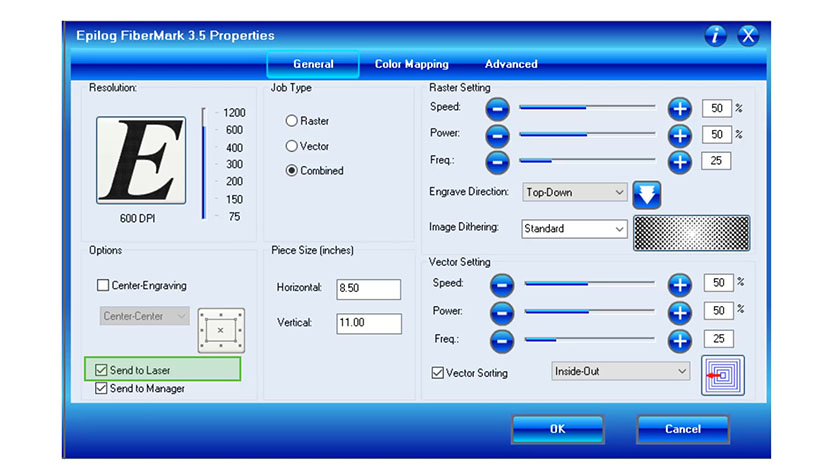

Now you can choose whether to send the job to directly to the laser…

…or to send the job to the Job Manager by checking ‘Send to Manager’ for quick access later.

Color Mapping Tab

Next, we’ll move on to the Color Mapping tab.

Color Mapping lets you set different speeds and powers to different colors within your artwork. Click the checkbox to enable the “Color Mapping” settings.

Change the speed, power, frequency, and focus for each color.

When you’re done adjusting your settings, click the right arrow to apply your new settings.

Advanced Tab

Finally, we’ll look at the Advanced tab in the driver.

The “Configurations” area of the driver allows you to save and access material and job settings. When your settings are perfect for a project, save them for the next time you need to run that job. You can also load our suggested material settings for materials into the driver from the driver download page on our website.

When you receive a notification of a firmware update on your system, select the “Update Firmware” checkbox, then load the file to start the firmware installation process.

For users that prefer the Legacy print driver Epilog has provided, select the “Classic UI” checkbox.

Under Language, you can change the language displayed on the print driver.

This was a basic overview of the Epilog FiberMark print driver. When you are done adjusting your settings, click the OK button to print the job to the laser or to send it to the Job Manager.